The purpose for this lesson is to teach grades 11-12 students the concepts of transistors, while also introducing electronics design software to digitally fabricate a transistor switch circuit. The challenge is to design a temperature activated switch that can also act as light activated by swapping one sensor. The output of this board can be used to control other electronic circuits, turning them on automatically either when it goes hot/cold or light/dark. High school students design this project to learn electrical engineering concepts such as; schematic/board layouts, soldering techniques, operating transistors, and the fabrication of circuits. Students have the option to go an extra step further by digitally fabricating their own circuit enclosure and designing their own marketing labels.

TOOLS/MACHINES

SOFTWARE

MATERIALS

Students learn the basics when it comes to regulating voltages and understanding transistors. Using transistors in a Darlington Pair is the heart of this project so in order to create the circuit students must first learn all of the components involved.

Before getting into the fabrication and design aspect of the switch, it is important to first explain to students why they are using transistors and what importance they have in the digital age.

Here is an example video of some simple explanations of a transistor: https://www.youtube.com/watch?v=7ukDKVHnac4

Some important factors to address when it comes to using transistors as a switch circuit:

Students will be introduced to the basics of Electronics Design using the KiCad software. All footprints for the components used are under Attachments as a .Zip file. This folder can be sync directly to KiCad for access.

This portion of the lesson must be taken slowly for high school students if the class has not yet been exposed to circuit design. The goal is for students to take an existing schematic and create their own board design that is 2″ x 1″ in size. Here are the two different schematics to choose how the switch performs:

Break down all of the essential features and tools of a design software (KiCad, Eagle, Etc.) in order to guide students in the following:

Students learn the next fabrication process by taking their finished circuit design into a milling machine. By taking an exported (Black/White) SVG file, they can then utilize the Fab Modules toolpathing software (www.fabmodules.org) to produce a circuit board.

The fab modules provide a set of software tools for personal fabrication, intended for use with machines common to fab labs. It Functions to generate 2D and 3D toolpaths for our circuit production and runs off any web browser from www.fabmodules.org. Once students are on the website, they first input the correct .SVG file they created earlier while also pressing “invert image” to get the correct contrast.

Once inverted, they must select the appropriate output file depending on the CNC Mill being used, and finally make sure that the toolpath is intended for “PCB Traces (1/64)”. See Below:

At the end they must hit “calculate” in order to generate the toolpath and then click “save” to make a G-Code specific to the previously chosen machine.

All CNC machine operations is then done at the instructor’s or manager’s expense and is specific to every Fab Lab.

Soldering All Surface Mount Devices (SMD) & Wires:

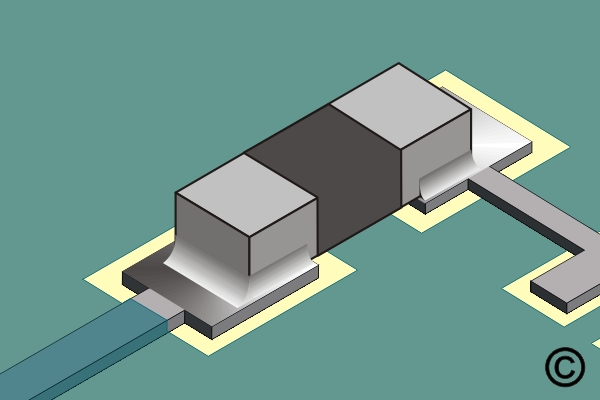

Solder the following components onto the appropriate pads based off the schematic design:

Students can either design their own 3D printed casing or produce the existing that I've attached to this lesson. Students can also design any custom labels from a vinyl printer/cutter onto their casings.

Having trouble? Let us know by completing the form below. We'll do our best to get your issues resolved quickly.

"*" indicates required fields